Wood and Earth

Building with wood and clay is as old as human existence. To describe the wood loam technique, it is possible to digress into an infinite number of techniques. We therefore limit ourselves to 2 wood loam techniques, with attached photos.

Loam with wood chips

A mixture of small pieces of wood with very oily clay. Let the mixture stand for at least 1 day, then fill the finished slats and reed formwork. Let the wall dry for 6 weeks before plastering it with clay plaster or lime plaster. Wood loam is not a load-bearing construction and must always have a self-supporting wooden frame! It is also important to always build with a roof overhang of at least 1 meter and with a plinth of 40 cm high in the splash area. The “Dry Hat, Dry Foot” principle.

This building system is particularly fast and therefore relatively cheap to build.

Loam with wooden slats and branches

Saw all slats and branches to the desired length of the wall thickness. Mix the base clay with water and apply the desired consistency. Brick the wood with the base loam and straw sawdust in the center of each wooden block.

As described in the first method ‘Loam with Wood Chips’

Is this is a more complex construction method and takes time.

Wood loam has a high insulation value. With its 700 kg / m3, the walls do not let the cold through and ensure a comfortable indoor climate.

Pavilion it ‘Raathuis’ ,

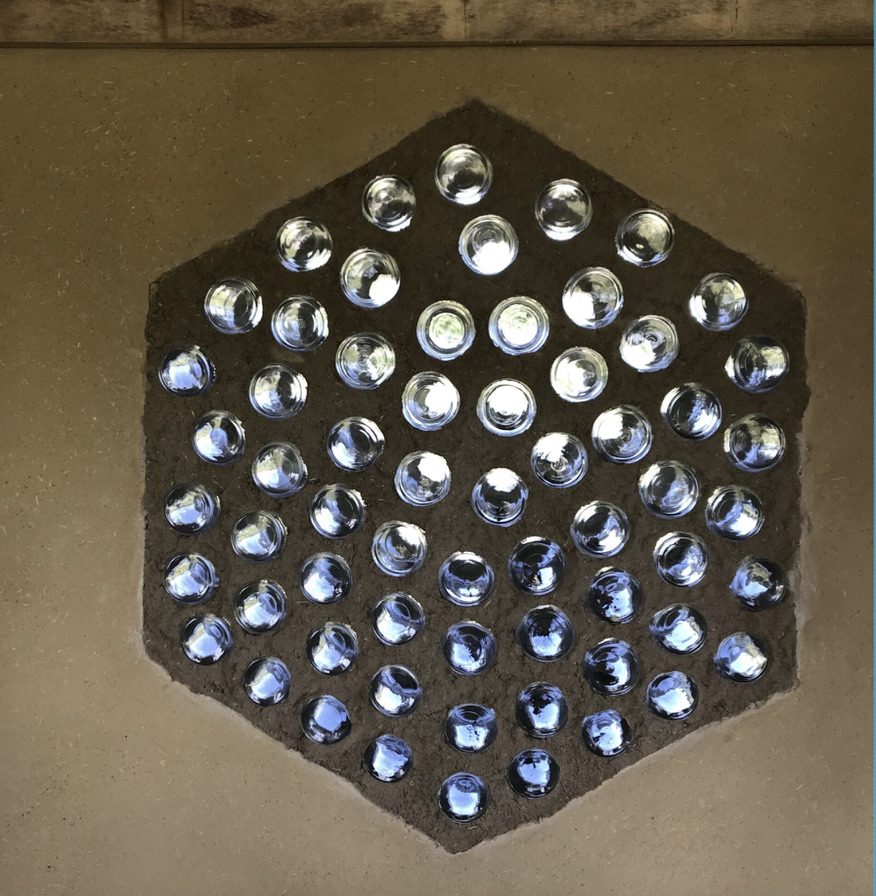

As seen on the banner photo above, its name is due to its honeycomb-shaped windows and its future function as a bee palace and also a meeting location, etc. Commissioned by the Fruittuin van West, the pavilion was built with abbreviated wood based on the Cord Wood technique and the principle of ZERO WASTE.

Cord Wood-technology

Originally a natural construction method in which short logs are stacked crosswise in a ‘natural’ mortar mixture to build walls. This technique uses local materials at minimal cost.

Stadshout (Amsterdam) was responsible for the design and execution of the construction, providing wood for the framework, residual wood for the construction of the walls, as well as sawdust for the composition of the mortar mixture, serving as additional insulation for the clay walls. Tierrafino supplied basic clay for the construction of the walls, handled the execution of the exterior walls, and plastered the interior walls with Duro clay stucco in a honey white and ochre color with straw.

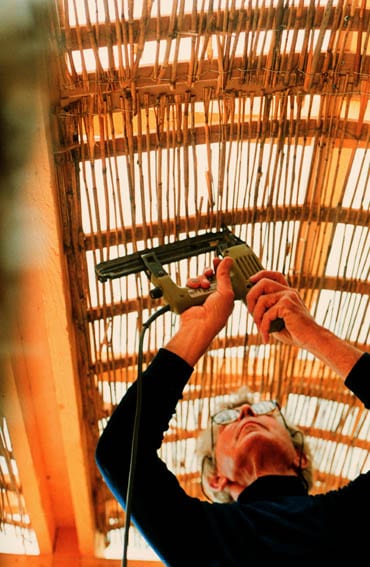

The walls are constructed of 2 horizontal loam dams, consisting of basic loam mixed with wood sawdust, which additionally increases the insulation value of the loam, 1 dam forms the outer wall and 1 dam forms the inner wall with wood shavings in between as insulation. Vertical wooden slats have been placed on these loam dams, on which in turn 2 loam dams have been placed, etc…..

It is a fairly simple but labour-intensive construction method. It is quickly learned and with many hands-on it goes considerably faster. The result is definitely worth it.

PAGE build the ‘Raathuis’ clik here!

Or read more on the pages below about the other clay construction techniques!

A title

Image Box text

Especially for professionals, we offer the Technical Friday Morning. In 1.5 hours, we provide explanations about earthen construction in general and the technical applications of our clay products. There are no costs associated with attending our presentation.

Sign up